For many businesses, throughput is a key performance metric that is constantly looked at, evaluated and tinkered with. At its core, throughput is measuring how many customers can be served per hour. And while throughput and speed of service are often interchangeably used, throughput is about a lot more than just speed and encompasses all elements of the customer experience. Particularly for the QSR industry, throughput includes efficient store layout, clear signage, preventative maintenance, division of tasks and proper employee training. It’s also about balancing efficiency with the same level of service that encourages customers to consistently return.

With a quick glance at how much the QSR industry leader, McDonald’s, invested in drive-thru technologies in 2019, it’s easy to surmise where the industry is headed and how it plans to maximize profitability. In late 2019, McDonald’s acquired Apprente, in an attempt to reduce wait times and increase throughput with voice-activated drive-thrus. Increasingly more QSR customers are using drive-thrus, and that trend is expected to accelerate with COVID-19 impacting consumer behavior. And while other players in QSR may not have the deep pockets of a McDonald’s, the need to meet changing consumer preferences and to invest in technology that improves drive-thru throughput have been made clear.

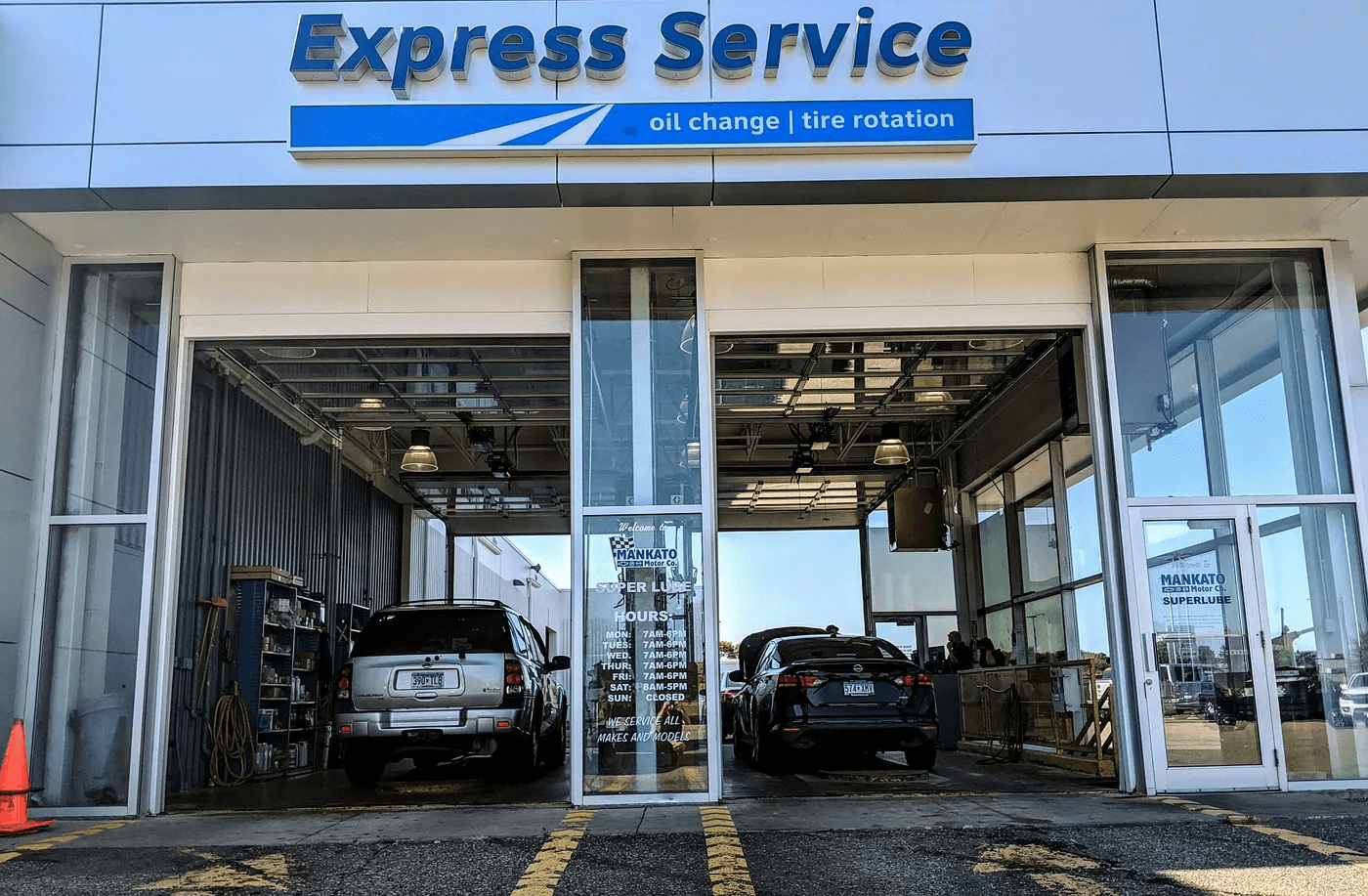

As with QSR, carwash companies are responding to shifting demands for a quick, convenient but still high-quality experience. Over 80% of new carwashes being built are express tunnel washes rather than labor-intensive and lengthy full-service or hand washes. Several of the best multi-store operations hone in on loader efficiency. If car loader A takes 1 minute to process a vehicle and car loader B takes 30 seconds, that’s a difference of 60 customers per hour! Shaving a seemingly insignificant 30 seconds per vehicle can actually double a store’s revenue and lead to happier, frequently returning customer base.

One of the best ways that an operation can optimize throughput is to step back, observe their everyday operations, and recognize bottlenecks in the flow of service. Prior to pouring extensive resources into consultants, new signage or building renovation, it’s critical for the manager to see when and where efficiency dips. By understanding at which times or shifts the operation is lagging, a manager can investigate and make informed decisions. In some instances, the fix could be as low-cost as moving shifts around to separate problematic teams and reduce interpersonal conflict amongst certain employees.

Companies relying on omniX labs reuse their existing camera systems to have real-time visibility on every unique visitor. By visually tracking wait time and visit duration, operators get an accurate picture of how to improve their throughput. Actively watching and comparing throughput trends over time allows management to get ahead early to diagnose and reverse downward trends. Alerting the managers in real-time when wait times are unusually high allows the operation to slam the brakes on potential disasters and salvage customer relationships.

omniX labs takes this a step further with deep learning algorithms, by providing accurate predictions for the next day. On high volume days, managers can increase labor to appropriately meet the demand. On low volume days, preventative maintenance, periodic training and any other “house-keeping” tasks can help avoid operational hiccups during the most profitable hours for a business.

Visit our website to learn more about how omniX labs can improve your operations.